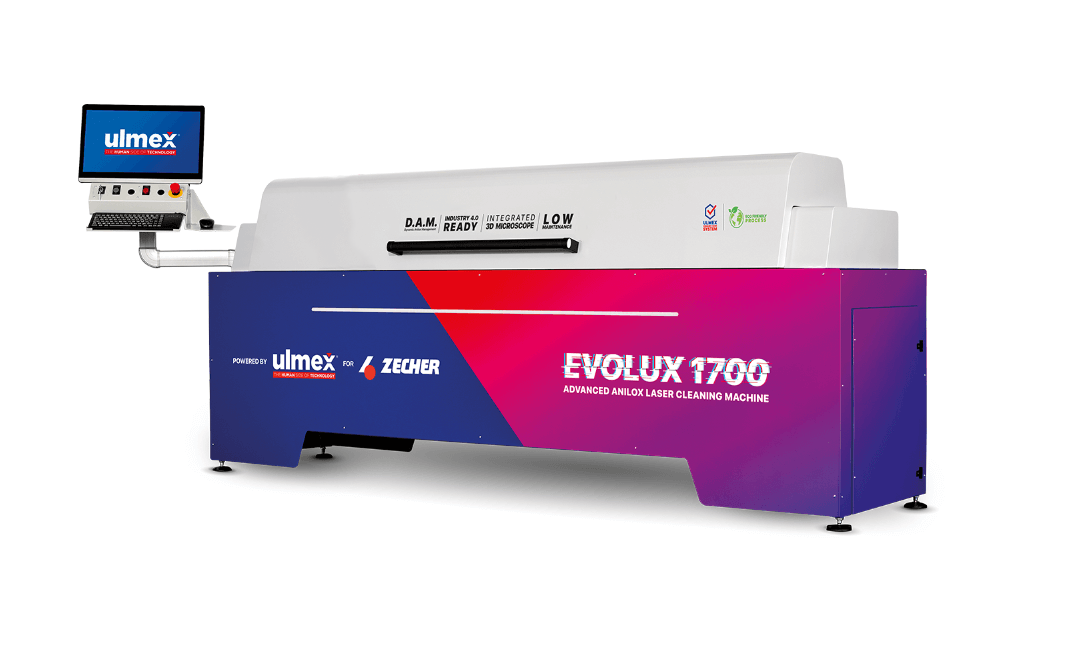

Why Evolux?

Individual cleaning programs

At the heart of Evolux technology is the pulse laser source. Unlike other types of lasers, which can only be regulated in terms of power, a pulsed laser is extremely flexible and also allows the user to calibrate the frequency and characteristics of the pulse.

Free of chemical cleaning agents and solvents

Evolux laser cleaning machines do not require chemical cleaning agents and solvents. This is particularly interesting in the food packaging sector.

Fully automatic cleaning process

No inspection by an operator is required and cleaning is always performed with maximum effectiveness.

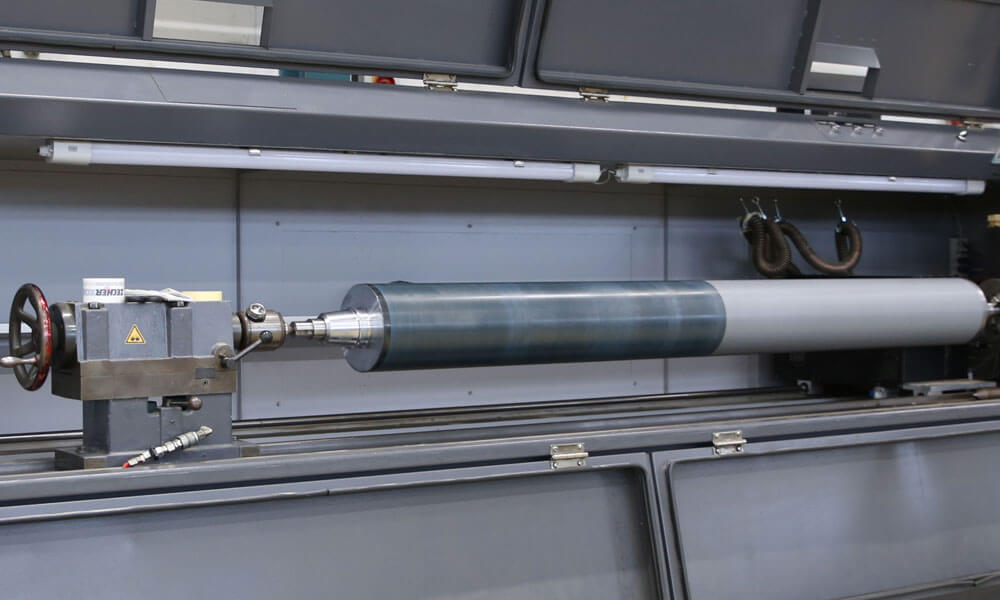

Removes even the most difficult residues

With the Evolux laser cleaning machine, you not only clean your anilox roller of ink residues, but residues of varnishes, adhesives, silicones and resins can also be removed without leaving any residues. No matter whether solvent-, water- or UV-based.

Uniform results

The autofocused laser beam cleans each individual cell of the engraving with the same intensity and energy. This technology enables consistent results along the entire length of the anilox roller.