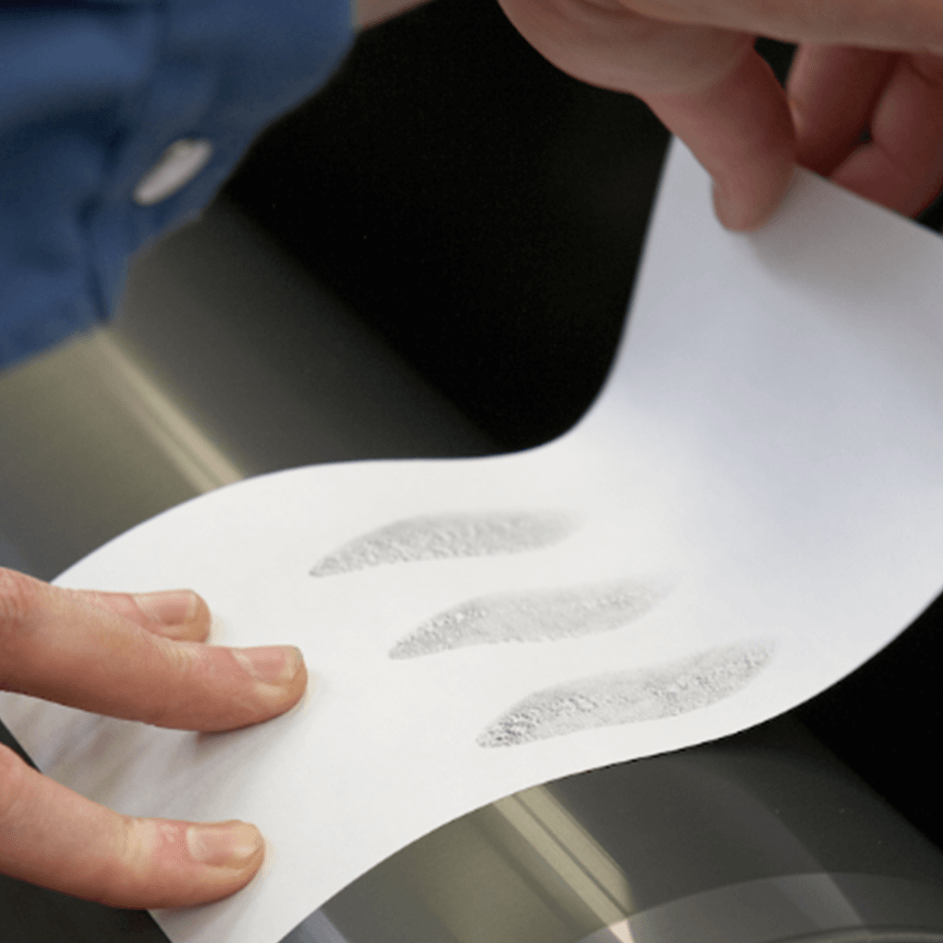

We are leaders in the use of the VoluCheck measuring system, which has been established for decades. Here, the scoop volume is determined by means of an ink impression after the application-related doctor blade process and subsequent planimetrization.

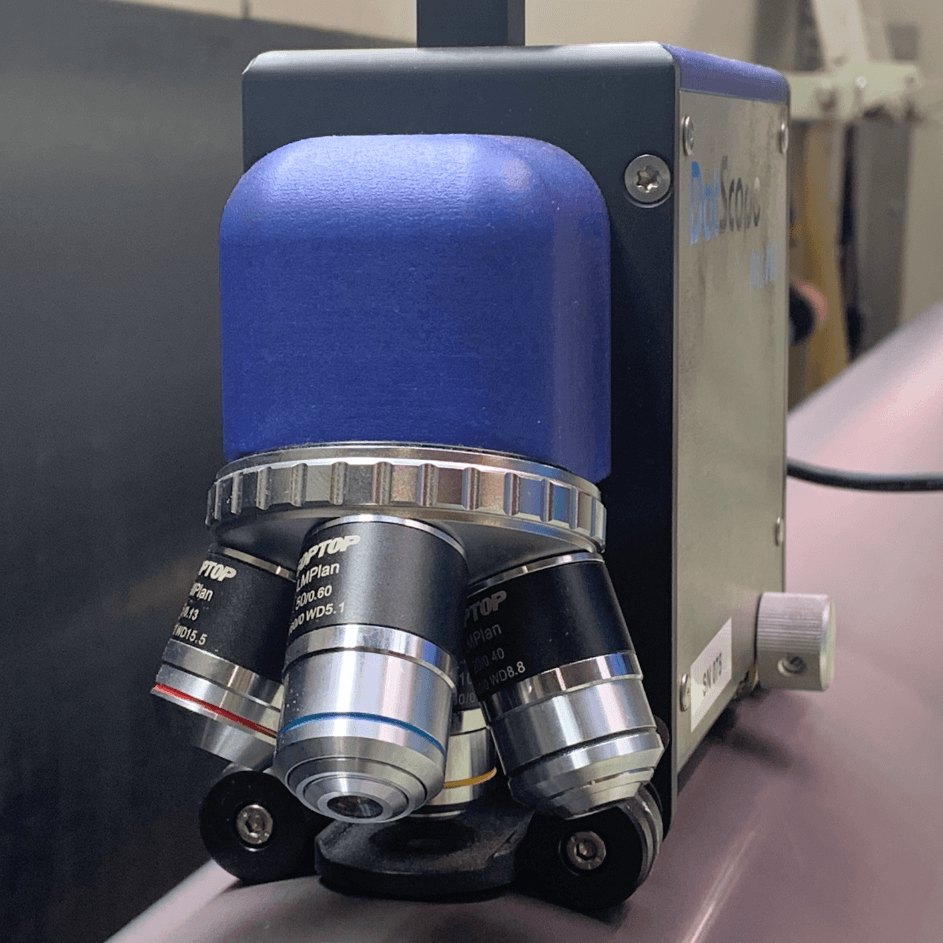

For a broader range, we have supplemented the analysis with the Dotscope measuring system. Both measured values are shown for you on the test report.

This extension gives you the option of choosing the measurement method that best suits your requirements. Unless otherwise stated, the VoluCheck method remains the determining one for the time being.

Our volume tolerances in production are +10% up to and including a volume of 6.0 cm³/m² and +7.5% from a volume of 6.5 cm³/m².