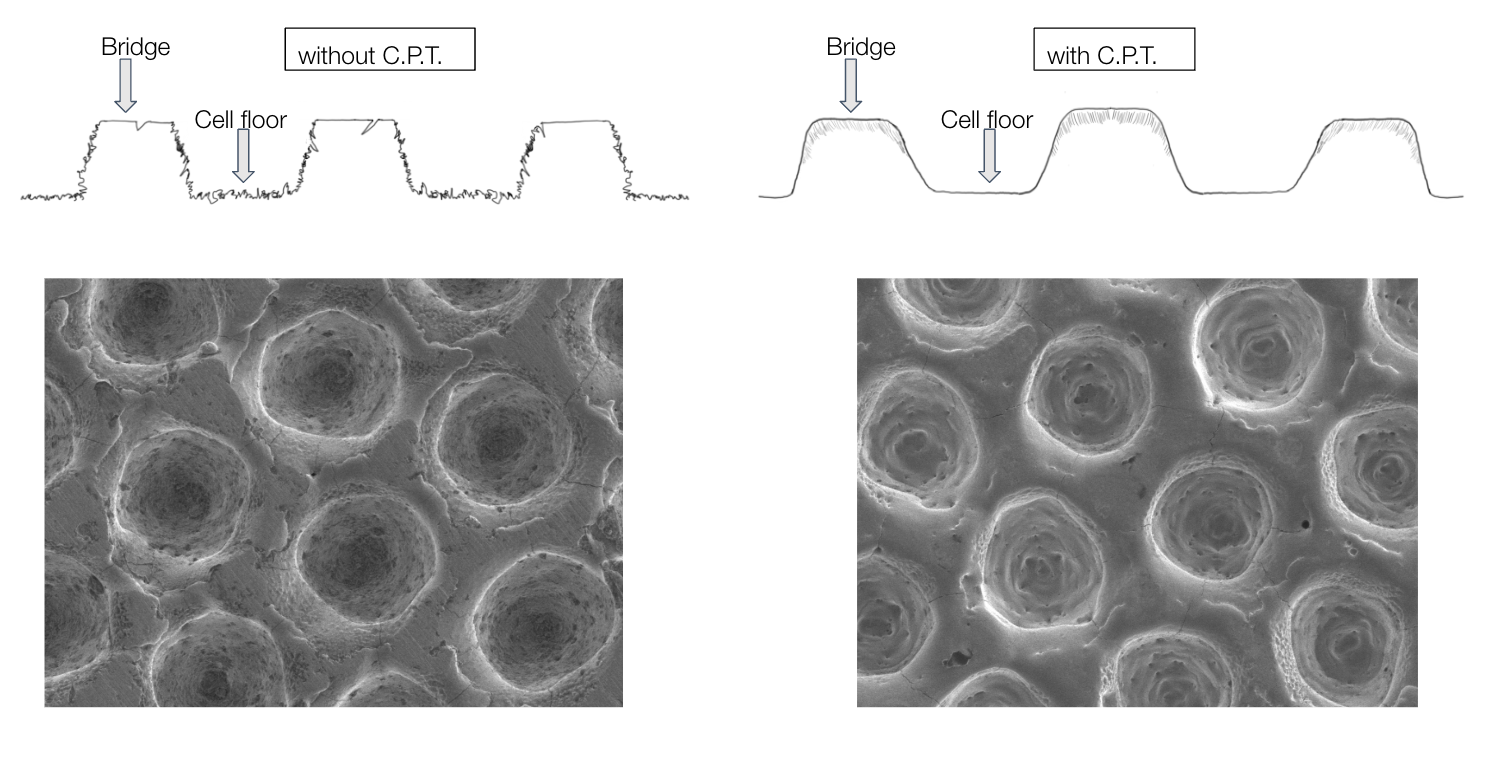

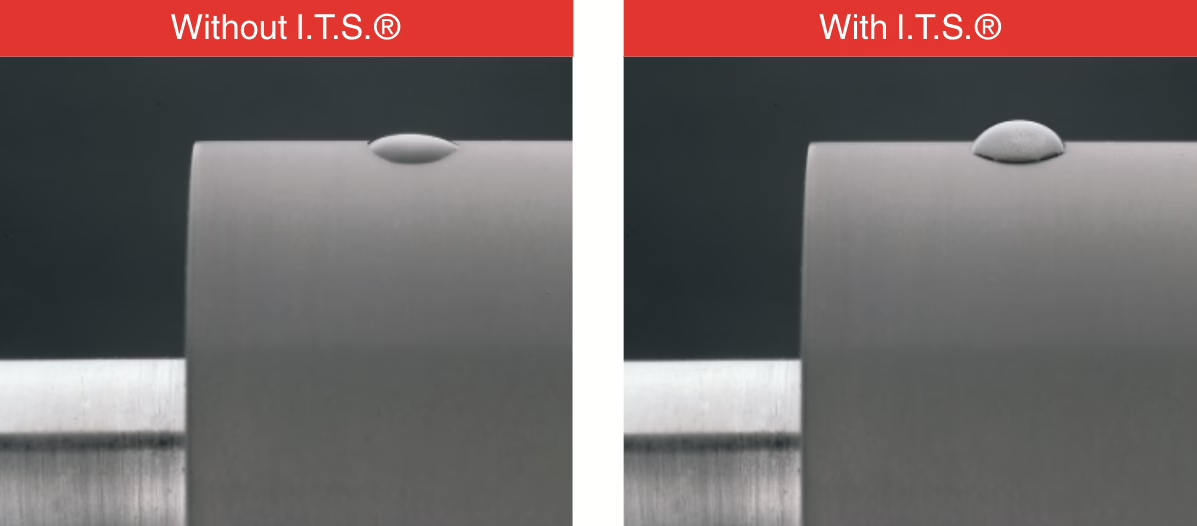

Our I.T.S.® treatment (Invisible Treatment System) ensures an optimized emptying process, allowing you to significantly improve the performance of your pressure rollers.

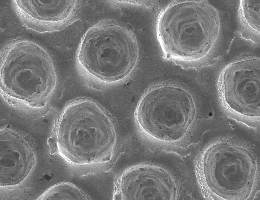

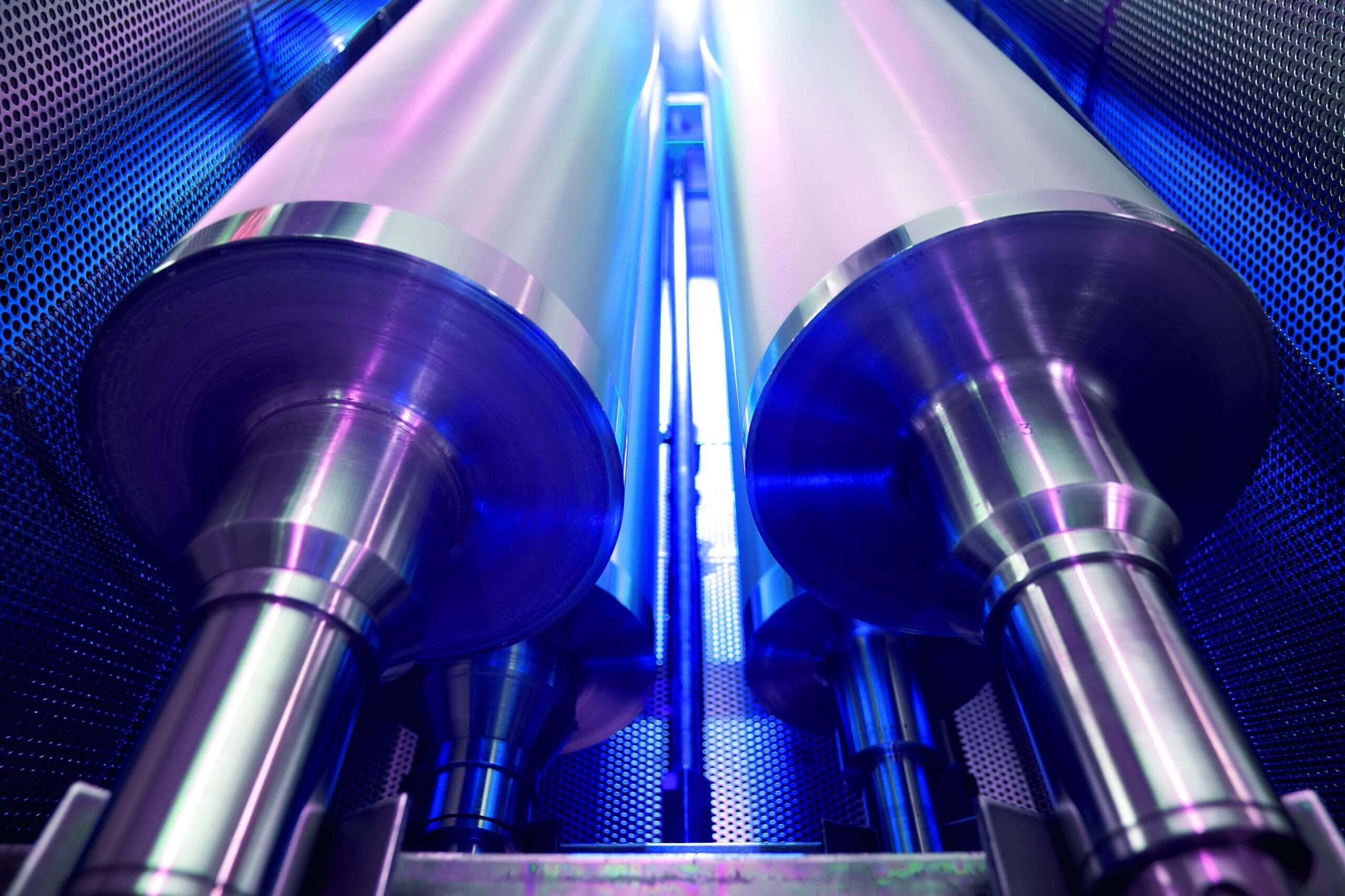

The patented surface finish changes the molecular structure of the ceramic material to make it denser. This is not a coating or sealing process, but a special vacuum process based on plasma technology that affects the structure of the chrome or ceramic layer to achieve specific surface properties.

The surface treatment reduces ink contamination from the very beginning by affecting the absorbency of the ceramic layer. Rollers treated with I.T.S.® therefore have a longer service life, improved emptying performance, and are much easier to clean. This particularly applies to ceramic rollers used in conjunction with water-based and 2K ink units. The treatment, which is invisible to the light microscope, does not wear off, does not peel off, and cannot be removed by external influences.