The chrome anilox roller corresponds to the original design of the anilox roller and consists of a steel or stainless steel roller blank. A copper layer is electroplated onto the roller blank of the chrome rollers. A protective chrome plating is then applied to the workpiece by means of an electrolytic bath, which gives the chrome anilox roller its name.

The chrome roller is mainly used in coating. Compared to a ceramic roller, the surface is much smoother and has better emptying. As copper is very soft, the engraving is protected against abrasive wear (doctor blade) by chrome-plating the surface.

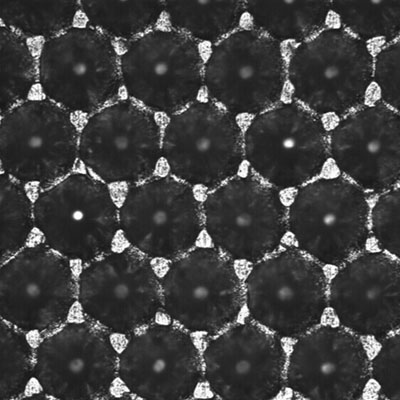

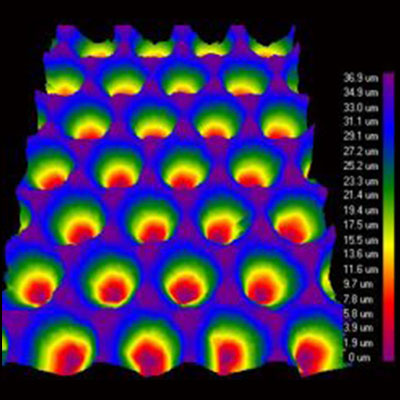

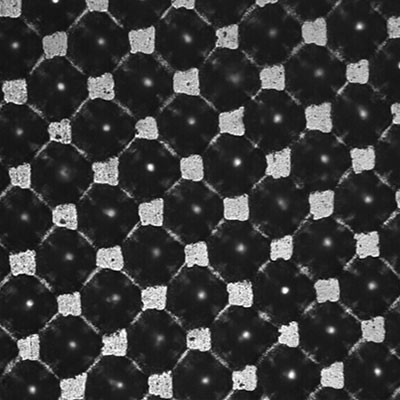

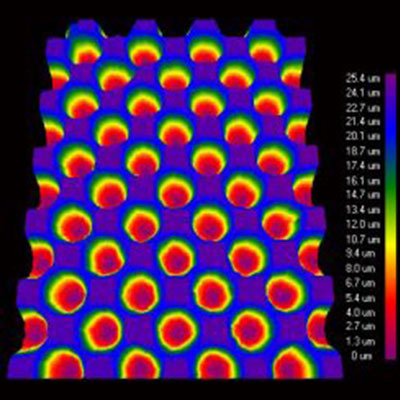

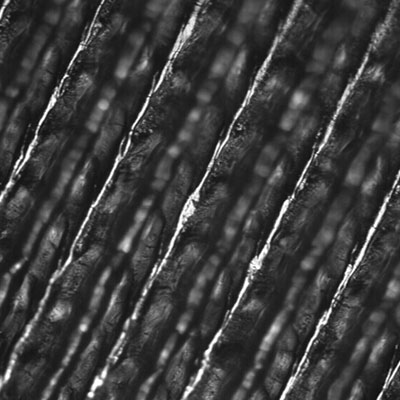

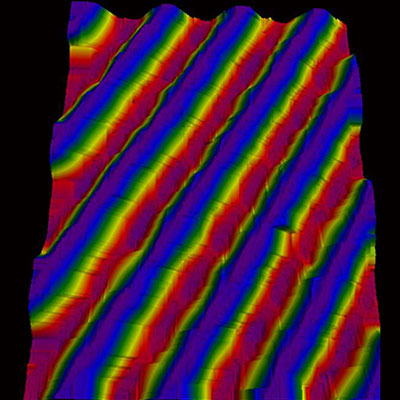

Diamond engraving for your chrome anilox roller

The engraving is made in a special copper-plated surface on the chrome anilox rollers. In this process, each cavity is individually struck by a diamond. Compared to other processes, electronic engraving offers absolute evenness of the cavity geometry and an optimum pick-up volume. We can tailor this process to your requirements.

Contact now