The Tresu iCoat 30000 Coating System includes a Flexo Kit for the application of effect coatings. Due to the high performance requirements of this system, it comes equipped with a Zecher anilox roller with H.I.T. or SteppedHex engraving.The Tresu iCoat 30000 Inline Flexo Coating System is an efficient solution for digital corrugated board printing. The iCoat coating system includes a “Tresu Flexo Kit”, a flexographic printing unit for the application of iriodine, gold, silver and other effect coatings. This system requires an anilox roller of the highest standard which promises an optimal printing performance and which is also suitable for water-based and UV coatings.

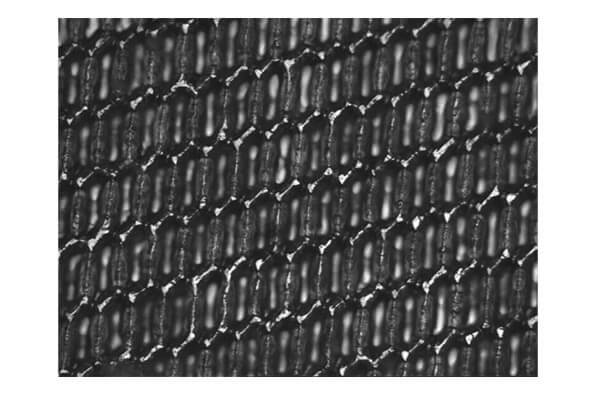

For silver and gold applications, the decision was therefore taken by Tresu to use the Zecher anilox roller with SteppedHex engraving (240L/cm; 12.5cm³/m²). At the same pick-up volume it has a higher detail rendition of positive and negative typeface and stroke applications. Furthermore, our SteppedHex engraving with special geometry ensures merged cells for a homogeneous surface coverage.

In addition, the Tresu iCoat System for iriodin applications comes equipped with a Zecher anilox roller with H.I.T.-engraving technology (80L/cm; 18.0cm³/m²) as standard. This special engraving impresses with its cell shape (suspended cell walls) which do not destroy the iriodin pigments, meaning that the desired effect can be achieved without restrictions.

The performance of this flexo coating system also was also presented at Dscoop EMEA 2017 in June. At this HP Graphic Solution Association event, other leading companies in the printing industry also presented their latest digital innovations alongside Tresu.