Function and areas of application of ceramic anilox rollers

Anilox rollers have become an indispensable technology for the printing industry. The corresponding equipment should therefore be just as progressive as the printing industry. That is why we have made it our business to offer you individual and innovative ceramic anilox rollers. These rollers are perfect for flexo and offset printing.

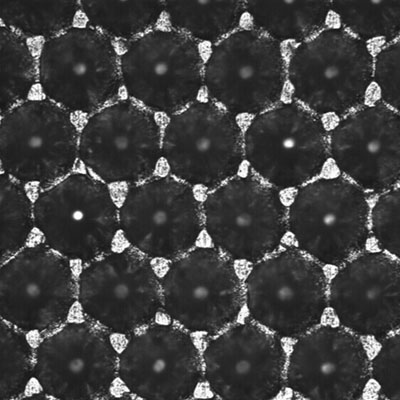

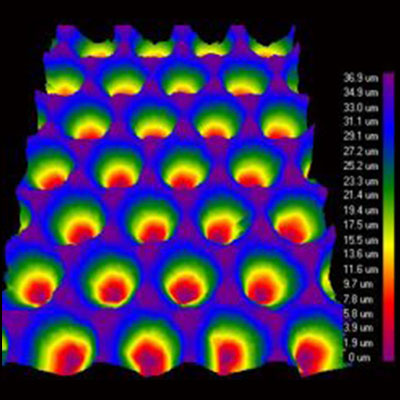

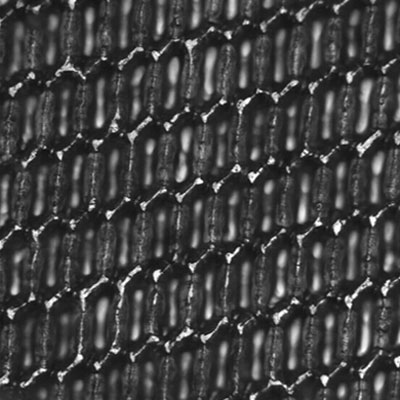

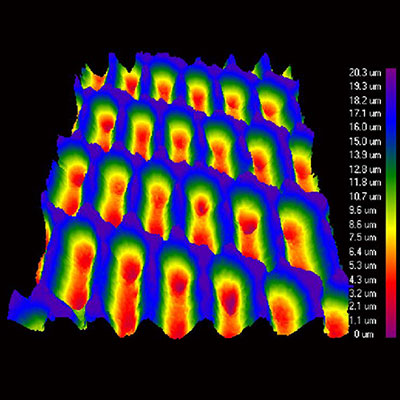

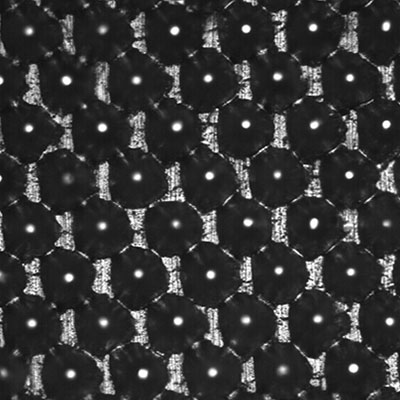

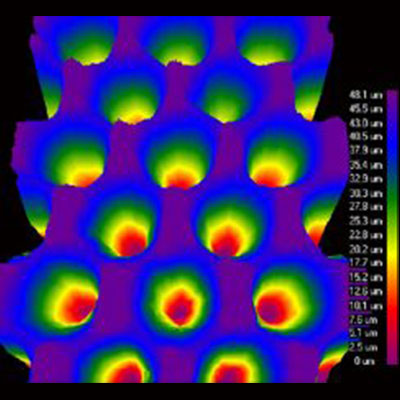

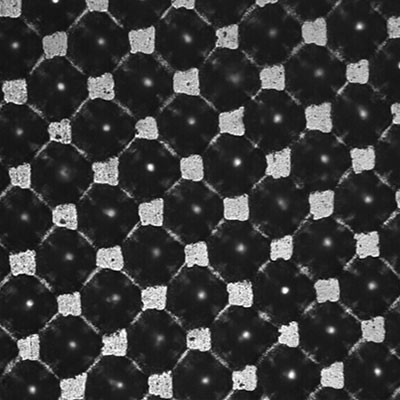

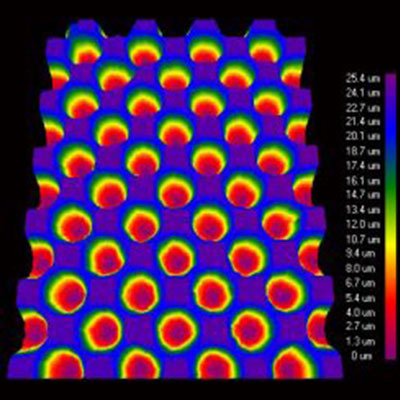

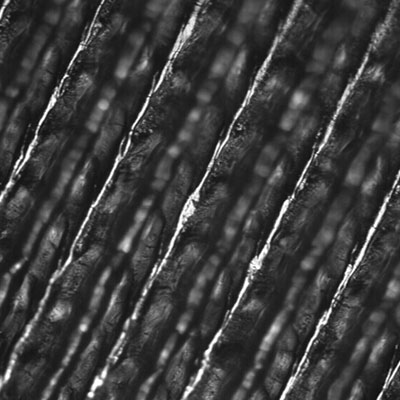

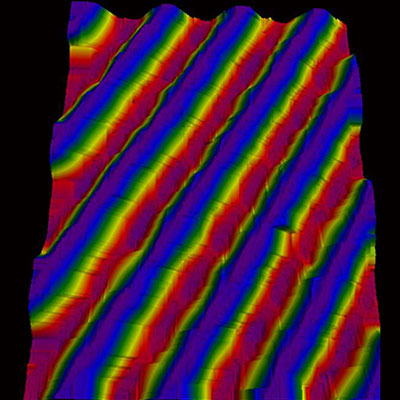

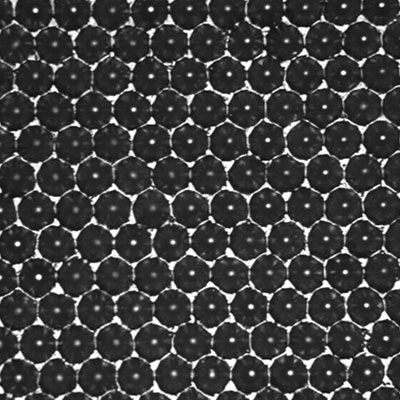

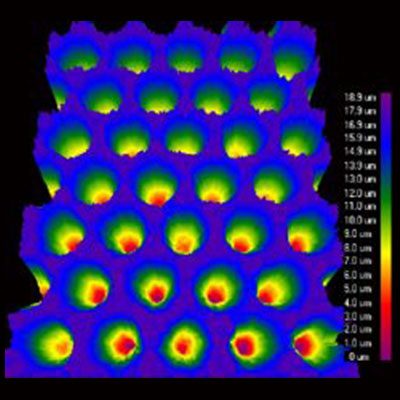

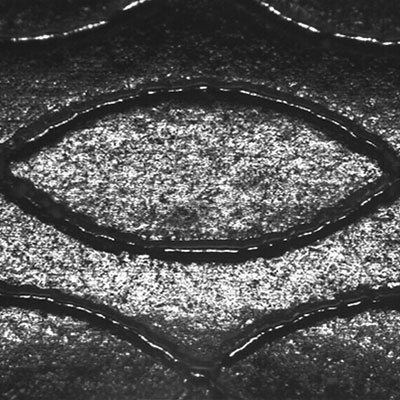

As early as 1982, a printing roller with a ceramic surface was used in the USA for the first time. Since then, innovative technologies have enabled ever better print results. Ceramic has the advantage for anilox rollers that the desired structures can be created very precisely with a carbon dioxide or YAG laser. In addition, ceramic is considered an extremely robust material and ensures a long service life for your ceramic anilox rollers.