Together with Heidelberger, we supported an end-customer with the best possible solution to print gold lettering. With the requirements of the end-customer in mind, we recommended the use of our innovative SteppedHex anilox rollers.

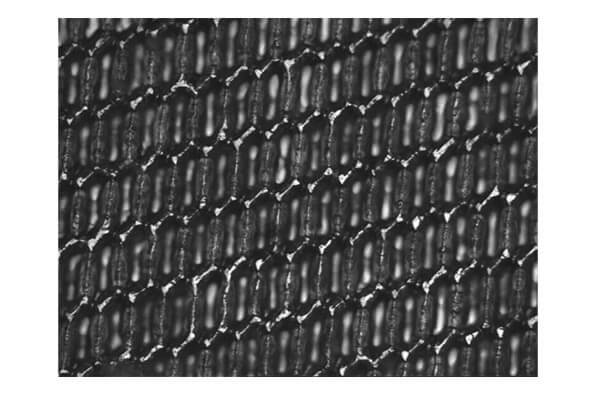

Our SteppedHex engraving assists the printer’s task with improved emptying of the anilox cells to deliver optimised printing results. This is proven by a series of successful SteppedHex-based projects carried out together with our customers. One such project, starting in early 2016, was a joint endeavour involving printing machine manufacturer Heidelberger, with a mission to provide an end-customer with the best possible solution to print gold lettering.

Cooperation-based search for the best customer solution

The cooperation with the specialists from Heidelberger Druckmaschinen included the provision by us of a corresponding technical-application analysis for the downstream varnishing/flexo printing works in relation to the print quality to be achieved. To ensure an ideal outcome, we also carried out test prints, likewise in collaboration with Heidelberger, at the Print Media Center (PMC) in Wiesloch-Walldorf (Germany), using a Speedmaster XL 106 double coating machine.

SteppedHex anilox rollers deliver outstanding results

Up until now the engraving specifications used for printing gold lettering have been relatively coarse. These include conventional, hexagonal 60° anilox engraving and the open line screen. With the requirements of the end-customer in mind, we recommended the use of our innovative SteppedHex anilox rollers. The engraving technology convinces with its special staggered structure and increased screen ruling without loss of volume. Initial test-prints carried out at Heidelberger’s PMC demonstrated these benefits in terms of excellent positioning accuracy and, at the same time, outstanding positive and negative detail rendering. The use of 240 L/cm SteppedHex anilox engraving amply fulfilled the end-customer’s expectations.

A clever solution that makes sense in both print-quality and business terms

Our SteppedHex anilox rollers provided Heidelberger’s customer with clearly improved printing performance. The application specialists at the Heidelberger PMC were positively surprised by the print quality delivered by SteppedHex technology. But this anilox engraving is also a clever solution when it comes to the printing of logos and fine gold lettering, given the cost savings in relation to the application of gold foil. In cooperation with Heidelberger we have created, with this project, a system that likewise gives other customers who use SteppedHex anilox rollers a way of guaranteeing a stable varnishing process. More and more customers are becoming interested in the possible range of applications of this technology, as an alternative to conventional anilox engraving. We therefore expect this innovative engraving technique to gain an ever-firmer footing in the market.